Despite the popular applications of the polymer powder materials in SLS, the volume ratio of powders that translate to parts is small, commonly 5% – 15% of the total powders in the build chamber. The 85% to 95% residual powders went through deteriorate physical and chemical degradations in the intricate fabricating processes, but have the potential to be recycled and reused for further applications. The deteriorated powders have reduced surface morphologies, larger and more complex molecular chains, decreased flowability, and deteriorated mechanical and thermal properties, challenging systematic material reuse. Also, polymer powder is relatively expensive, and abandonment of the residual materials can cause not only environmental pollution but also economic losses.

The Reutilization of Polymer Powder Materials in SLS

With customized process control, powder mixing, and hardware reconfiguration on our in-house built SLS testbeds, we 3D printed with reclaimed PA2200 powders at different degradation levels.

Tensile bars using 50%-50% new-aged mixed powders with 10 layers

Tensile bars using 30%-70% new-extremely aged mixed powders with 10 layers

Tensile bars using 30%-40%-30% new-aged-extremely aged mixed powders with 10 layers

Material and Specimen Characterizations

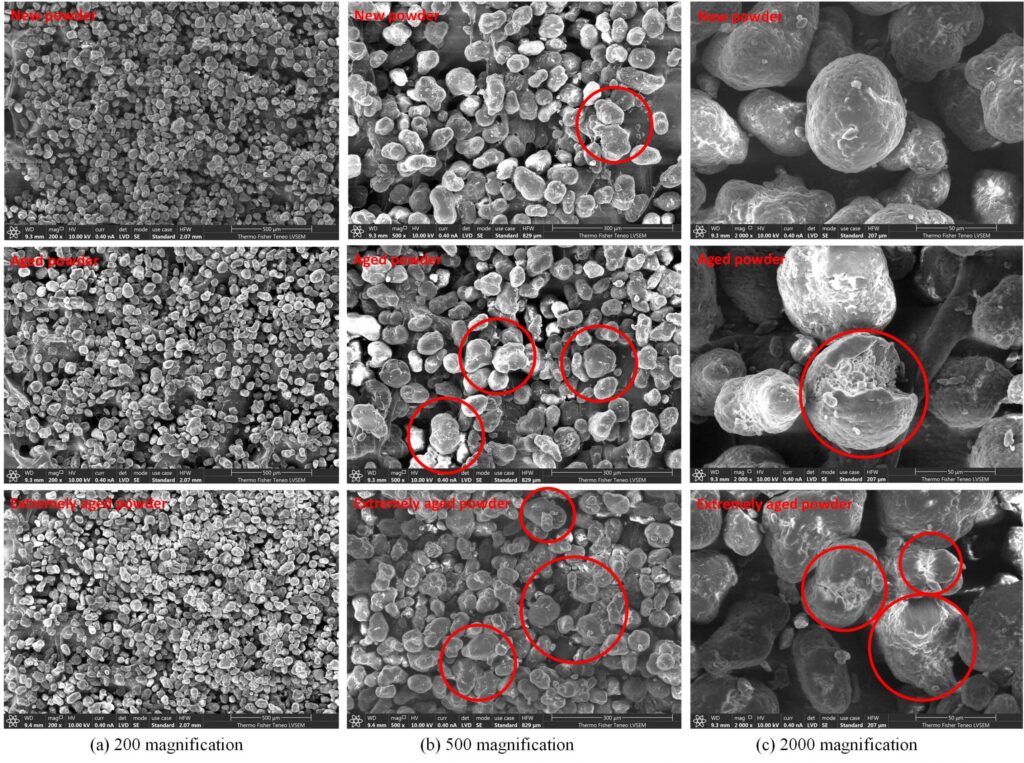

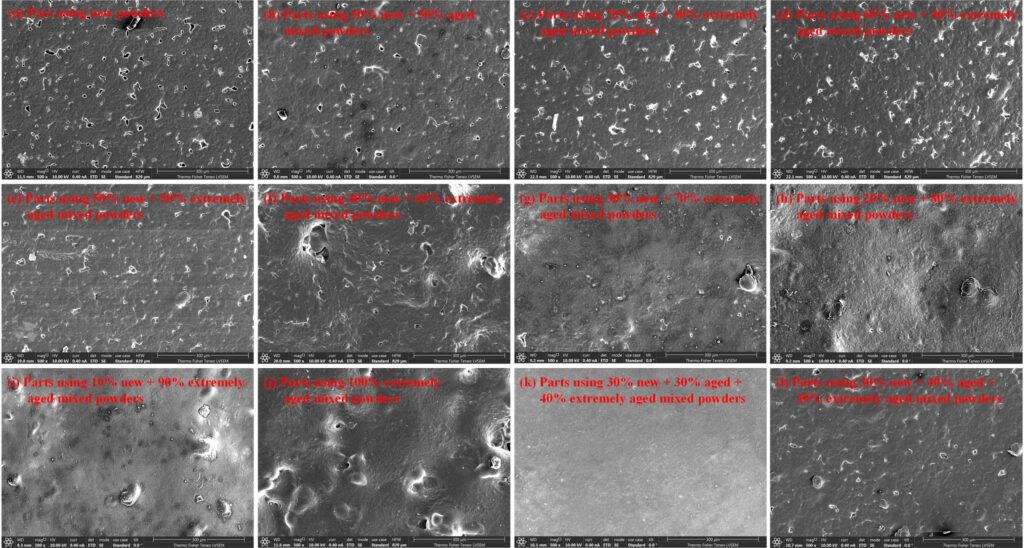

Our goal is not only to create new engineering processes, but also to understand the ins-and-outs of the physical process. We evaluated the 3D printing results with scanning electron microscopes (SEMs), differential scanning calorimetry (DSC), Fourier-transform infrared spectroscopy (FTIR) and X-Ray Diffraction (XRD) to understand microscopic material properties. We also performed such mechanical testing as tensile tests to exploit the achievable structural properties.

SEM results of PA2200 powders

FTIR results of PA2200 powders

DSC curves of PA2200 powder samples and part samples

Reclaimed Materials with Improved Properties

Surprising at initial sight, we can not only control mechanical properties and surface morphologies of parts with reclaimed materials, but also exceed the nominal value from parts 3D printed with new powders.

Stress-strain curves of samples with improved tensile strength

Improved part surface morphologies