3D Defect Detection for Industrial Automation

We develop state-of-the art approaches for detecting defects in manufactured parts via analysis of their 3D shapes

3D Defect Detection for Industrial Automation

Robotic quality inspection is rapidly advancing as a frontier in intelligent manufacturing, where robots extend beyond human limitations in consistency, endurance, and access to challenging environments. A detector, such as a high-resolution 3D scanner, is mounted on the robotic arm, which then maneuvers it to capture the surface geometry of the inspected part. The collected data is analyzed to identify and localize defects.

Much of the current research focuses on detecting defects from the high-resolution 2D images. However, defects in industrial parts often manifest as geometric deviations (e.g., deformations, missing or extra structures) rather than texture changes. With that in mind, we leverage modern AI to develop efficient, accurate methods for 3D defect detection.

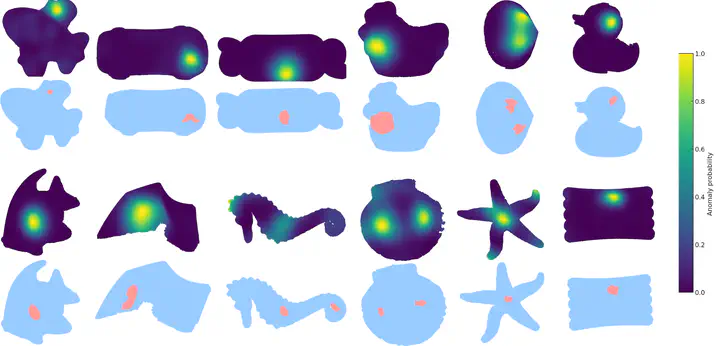

We use deep learning to extract the most informative representations of a part’s surface geometry. We train our deep network on a variety of 3D shapes and defect types, enabling it to generalize well to unseen geometries. During the inference, our trained network extracts representations from the new, previously unseen parts. We perform a statistical comparison of these representations against a library of known geometries extracted from defect-free parts.

The scarcity of training data has long been a limiting factor for deep learning techniques in defect detection. We carefully combine proven 3D vision techniques with state-of-the-art deep learning models to produce a system that efficiently utilizes every bit of a training set. Our models are trained on a consumer GPU, which is important for the targeted manufacturing application. At the same time, our approach delivers superior accuracy on Anomaly-ShapeNet and Real3D-AD datasets for 3D anomaly detection.