Preheating Temperature Control and Low-Contrast Imaging Data Analytics for Laser Powder Bed Fusion

Abstract

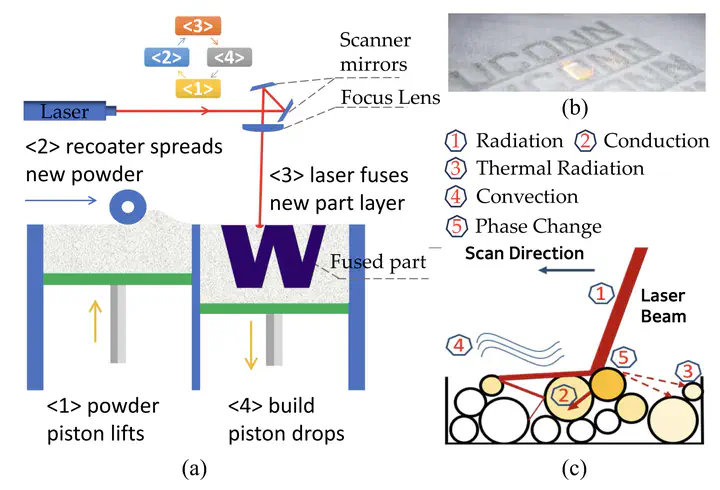

Laser powder bed fusion (LPBF) additive manufacturing has seen widespread use for its unique advantages in achievable part complexity and processable materials. However, greater applications of this technique remain hindered by the insufficient assurance of part qualities. A major barrier to such a long-felt but not fully realized quality assurance arises from challenges in sensing and model-based control, particularly when involving materials showing low contrast under laser radiation. This article presents two advances that contribute to this vista. We 1) propose a model-based multizone heating control for minimizing the powder bed temperature deviation in the presence of part-geometry-induced crosslayer thermal disturbances and 2) create an image analy tics framework for process monitoring of low-contrast material LPBF with visible light cameras. The proposed methods are developed and verified on an in-house built feedback-centric LPBF platform.