Effect of Intra-Build Design Parameters on the Fracture Toughness Properties of EBM Ti6Al4V

Abstract

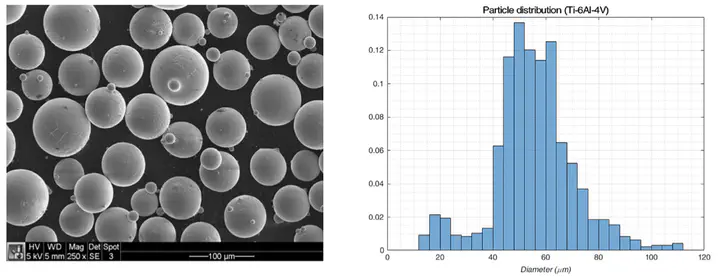

Metal additive manufacturing technologies provide new opportunities for manufacturing complex components. However, the limited data on fracture behavior are delaying adoption in safe-critical applications. This paper aims to evaluate the effect of orientation and the intra-build design parameters on EBM Ti6Al4V fracture toughness using a design of experiments. Three builds comprised of over 150 compact tension samples were printed representative of the EBM build chamber, followed by microstructural characterization, X-ray microcomputed tomography, and fracture toughness testing per ASTM E399. The average fracture toughness was 65 MPa square meter, with anisotropy as the largest source of variation due to crack growth behavior with respect to the build direction. Microstructure coarsening was observed with increase in height, resulting in an increase in fracture toughness, irrespective of sample geometry or orientation. Build orientation and sample location influenced the microstructure and fracture toughness and should be considered when adopting EBM components in load-bearing applications.